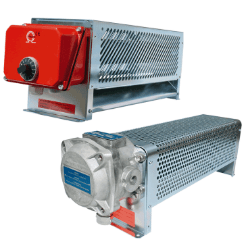

Barrel-mounted immersion heaters

Definitions and general information

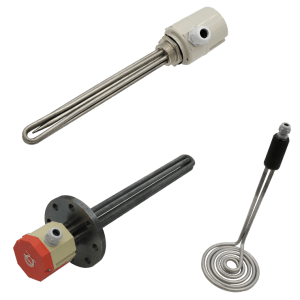

Barrel-mounted immersion heaters are designed to heat liquids (water, oil, fuel oil, glycol, acid, soda, bitumen, etc.) directly or via a stainless steel immersion sleeve (304L or 316L), or long metal parts (trays, molds, etc.) by natural or forced convection, up to 15 kW, 400 V single or three-phase.

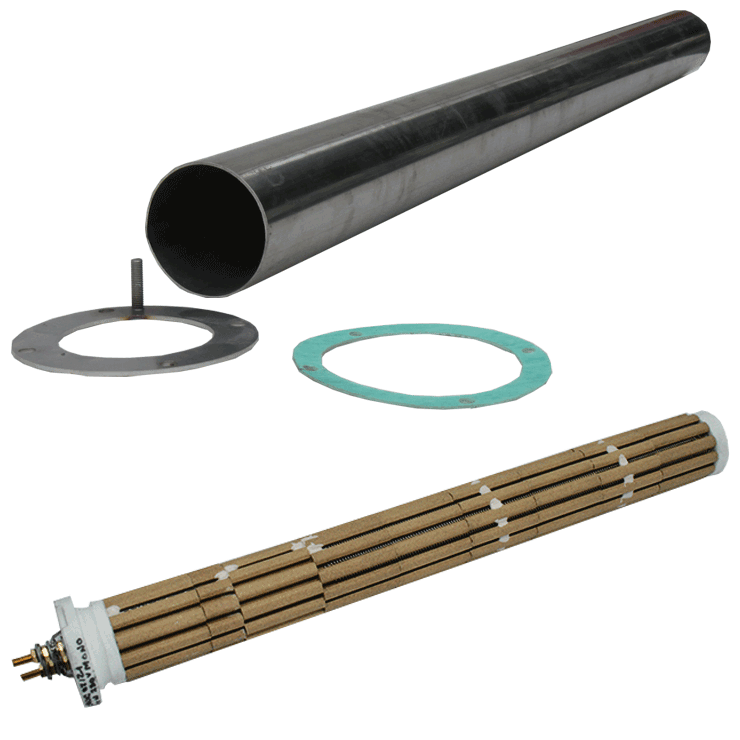

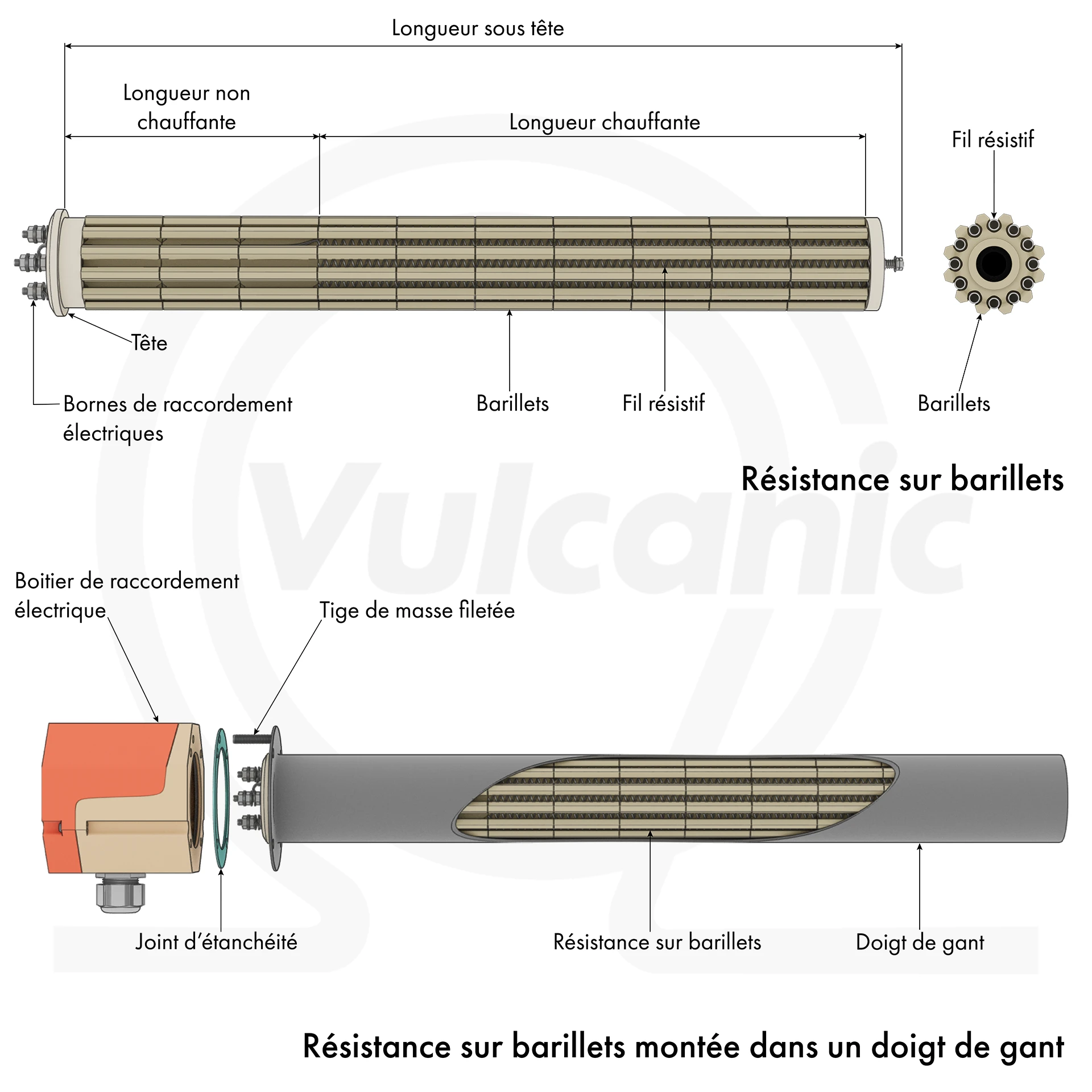

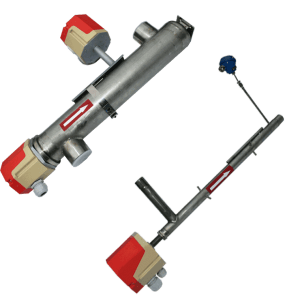

They are made up of nickel-chromium wire resistors wound into coils and mounted in steatite electrical insulating elements called barrels, screwed onto a threaded sleeve (metric or gas thread) or mounted on a counter-flange complying with EN 1092-1 or ASME B16.5 standards. The heating length can reach several meters, limited by the maximum current condition.

This technology makes it possible to replace the heating resistor without having to dismantle the entire immersion heater or drain the tank containing the fluid to be heated.

Implementation

Technical data

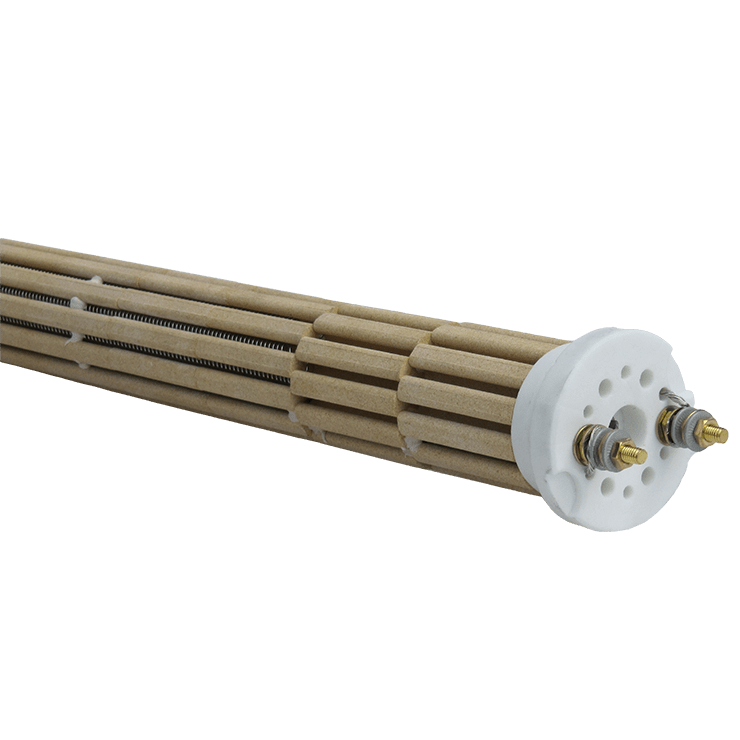

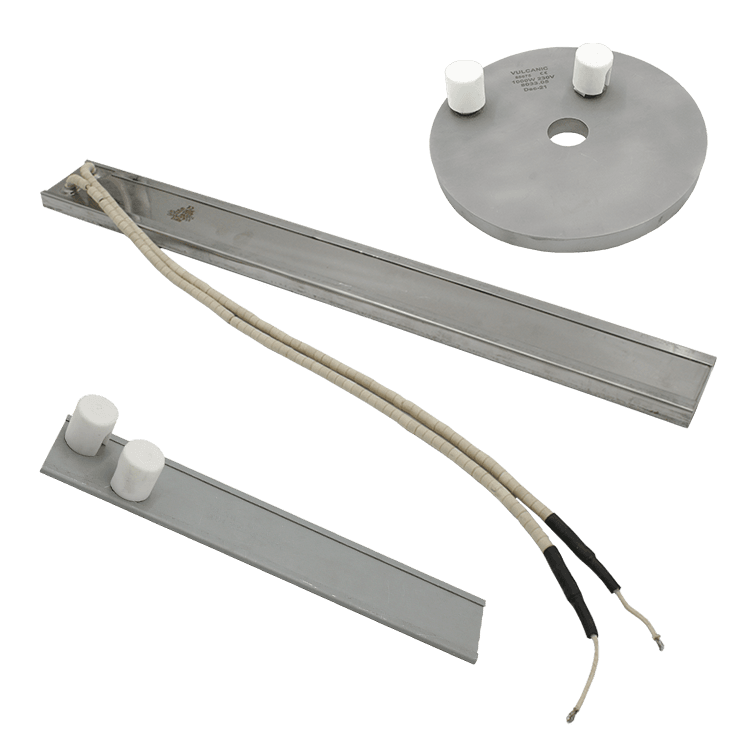

These RSB immersion heaters consist of :

- Nickel-chromium resistive wires wound into coils and mounted in electrical insulating elements

- Barrels are cylindrical ceramic (soapstone) elements in which resistive wires are wound.

- Electrical terminals for immersion heater power supply. Several terminal models available (threaded, with holes, flat, Faston) or direct wire outputs.

- The stainless steel (304L and 316L) thermowell (optional) containing the barrel resistor can be welded directly to the tank wall, screwed onto a threaded sleeve (metric or gas thread) or mounted on a counterflange complying with EN 1092-1 or ASME B16.5 standards.

- A polyamide electrical cover (optional) to protect the heating element connections from physical damage. The electrical supply is connected to the immersion heater by a gasket.

Accessories

Barrel heaters can be fitted with :

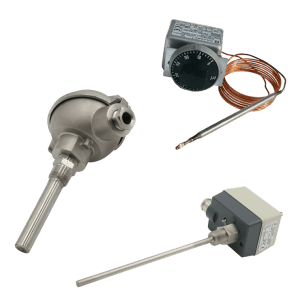

- A control or safety device (Pt100 sensor, thermocouple or thermostat) installed in a thermowell to measure the temperature of the fluid or heating element.

- A gasket available in various materials (fiber, metal-plastic, etc.)

- A threaded grounding rod connected to a ring connecting the device to ground.

Recommendations

Precautions for use

Check that the diameter of the thermowell (in the case of liquid or gas heating) is compatible with that of the barrels: It should be as close as possible to that of the barrels, taking into account their tolerance.

Check that the inside of the pocket or bore is perfectly clean, with no trace of metal shavings,

water, moisture or oil.

Installation and connection

Preferably use glove fingers and junction boxes for heating liquids.

For applications where the temperature inside the thermowell is likely to exceed 500°C, remove the central spindle at the time of installation: only the horizontal installation position is possible in this case.