Heating solids

External conduction heating

Setting the scene

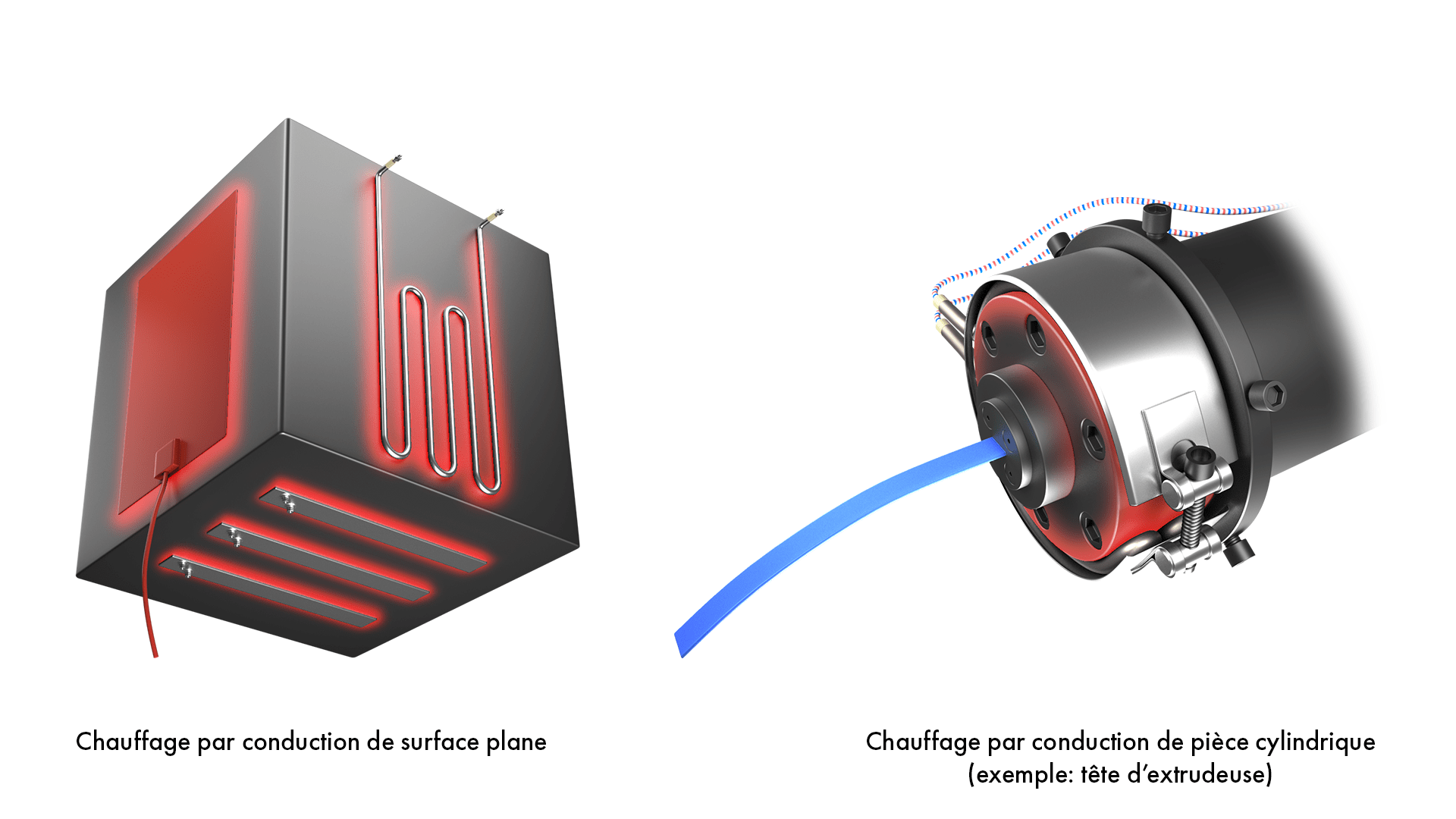

External conduction heating using electrical resistances is a process that involves transferring heat generated by the heating element directly to a material or equipment through contact, without the need for an intermediate fluid. This heating method, suitable for flat or cylindrical parts, is used in the plastics industry to hold molds or extruder heads. In metallurgy, it allows parts to be preheated before welding or heat treatment. External conduction heating ensures a rapid and uniform temperature rise, without energy loss.

Our product range for external conduction heating

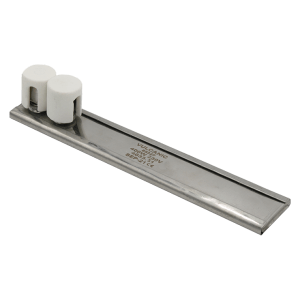

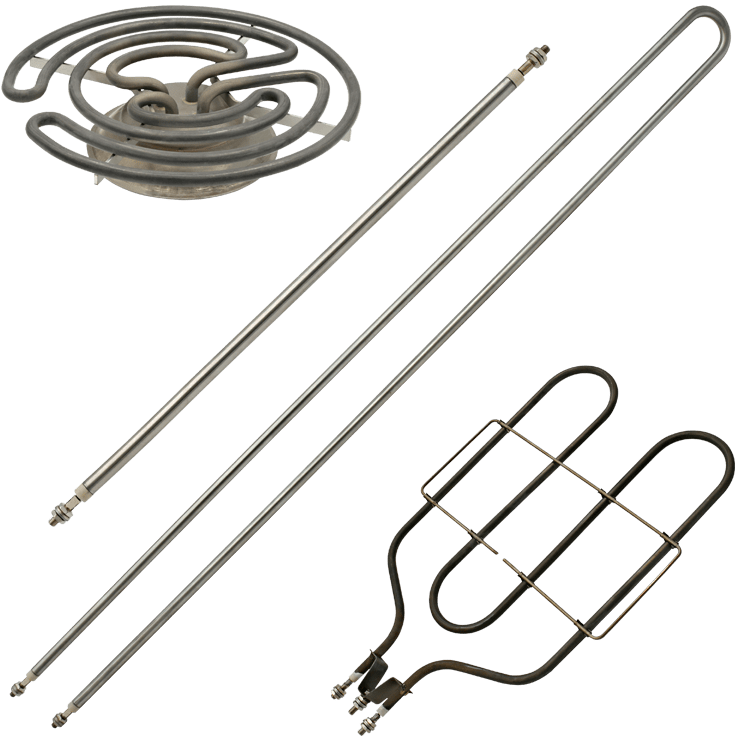

Bare shielded heating elements

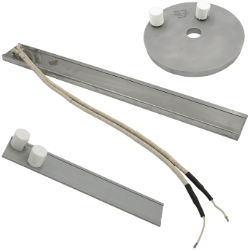

Silicone heating panels

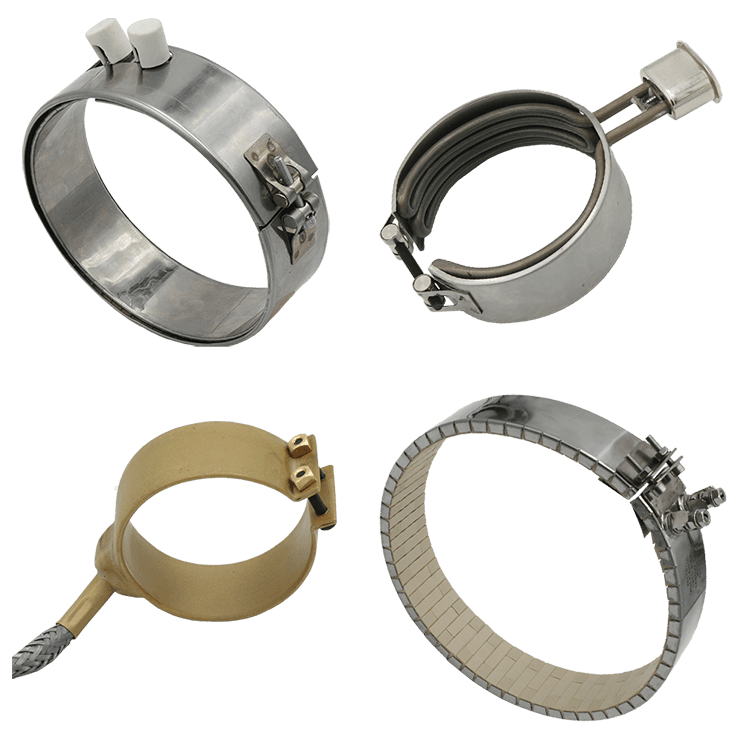

Heating collars

Flat resistors

Internal conduction heating

Setting the scene

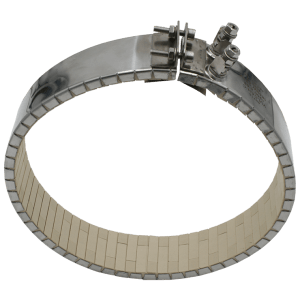

In the industrial field, internal conduction heating is a commonly used method to ensure efficient heat transfer to the very heart of equipment or material. This process involves directly integrating the heat source, either through electrical resistors inserted into the part to be heated, or through the circulation of a heat transfer fluid (water, oil) in internal channels, in order to obtain a uniform and controlled temperature rise. This heating method is particularly suitable for the manufacture of composite and plastic parts and the production of heating plates and tables. Internal conduction heating guarantees uniform heat distribution directly to the heart of the material.

Our range of products for internal conduction heating

Vulcatherm® temperature controllers

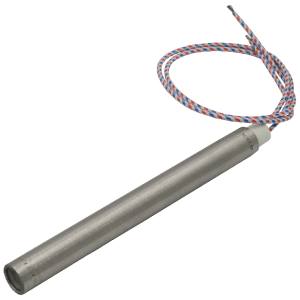

Cartridge heaters

Radiant heating

Setting the scene

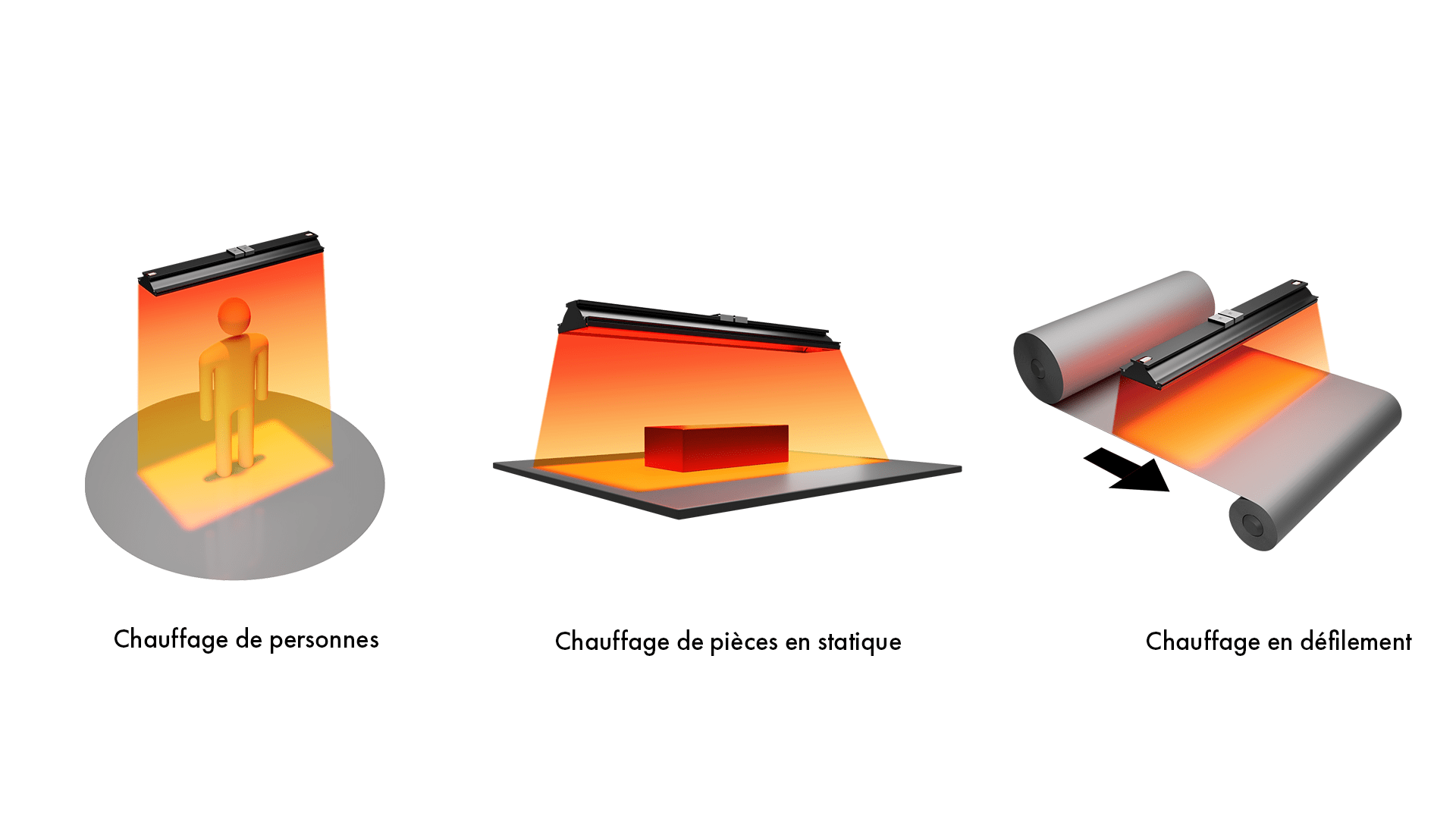

Radiant heating uses infrared generators, usually in the form of lamps or panels, which emit radiation that is directly absorbed by the targeted surfaces, without heating the ambient air. Depending on the specific needs of each industrial application, different infrared wavelengths (short, medium, long) are chosen to optimize heating efficiency. This process is particularly suitable for heating work areas or operator stations. In static heating, it can be used to preheat components before assembly or processing. In addition, in continuous production lines, infrared radiation is ideal for quickly heating moving materials such as plastic films, sheet metal, or technical textiles.

Long-wave infrared generators

Mid-infrared generators

Shortwave infrared generators